Polyflake Products provide advanced corrosion protection for marine, offshore, and industrial assets worldwide. Engineered for extreme conditions, Polyflake Products deliver 25+ years of proven performance while cutting costs by up to 70%

Corrosion costs industries over $2.5 trillion annually worldwide (source: NACE International). Equipment replacement, unplanned downtime, and frequent recoating drain budgets and disrupt operations across marine, offshore, oil & gas, and industrial facilities.

“For over 37 years, Polyflake Products have helped marine and industrial operators reduce costs and extend service life.”

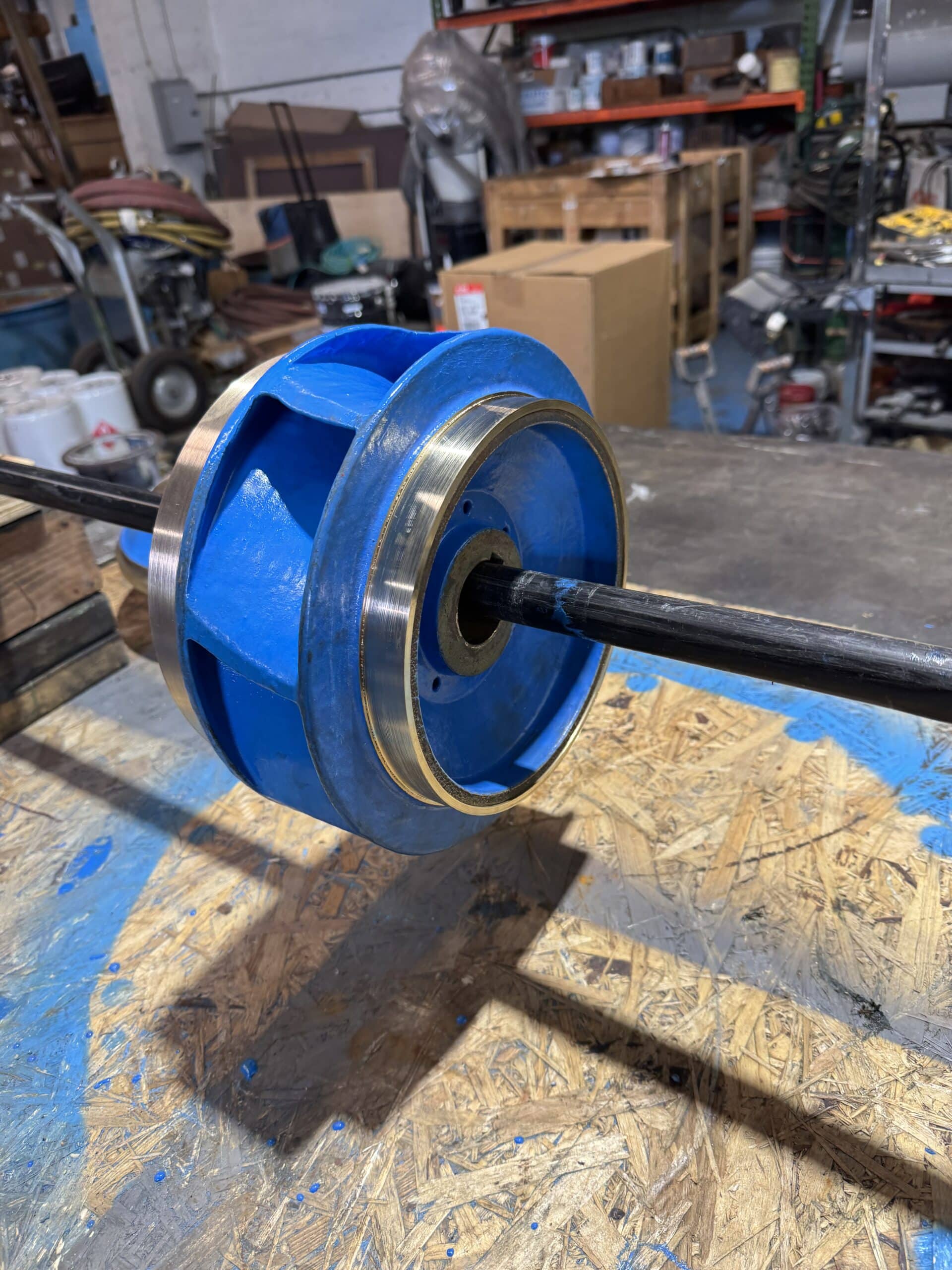

Our advanced glass flake coating systems create an impermeable barrier against seawater, abrasion, and chemical attack.

25+ years of proven protection in real-world deployments

Up to 70% lower lifecycle costs vs. conventional coatings

Fewer shutdowns & reduced downtime → maximized operational efficiency

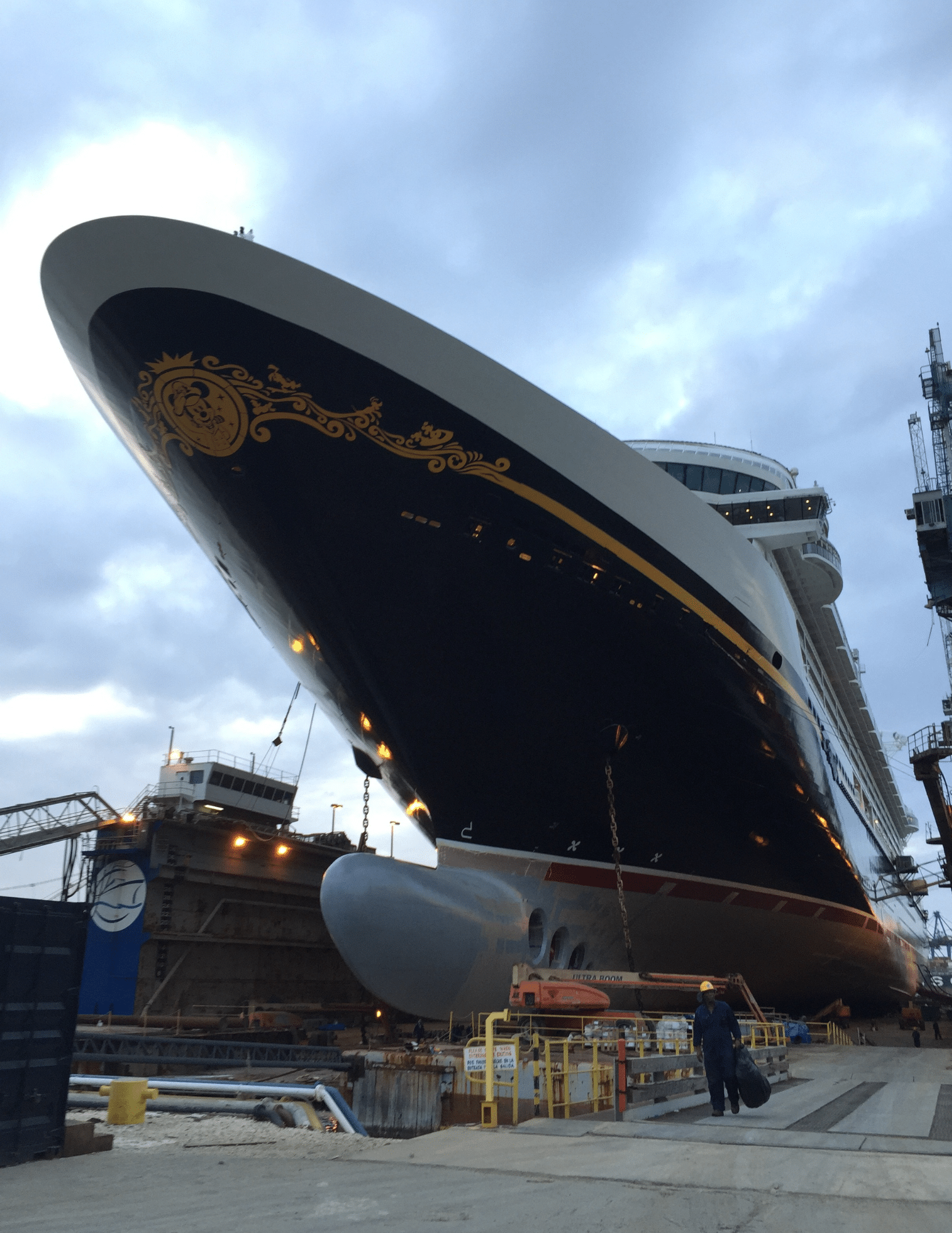

Discover how Polyflake® POLYGLYDE Hull Coatings reduce drag, improve efficiency, and cut fuel costs for marine vessels.

Detailed technical specifications, certifications (NSF, ISO), and performance data for our advanced glass-flake coatings.

Polyflake® coatings use precision‑engineered C‑glass flakes and high‑performance resins to create a dense, tortuous barrier that blocks moisture and chemicals, delivering 25+ years of protection in marine, offshore, oil & gas, and industrial environments.

“Polyflake Products are engineered to withstand extreme conditions with proven performance.”

From our beginnings in New Zealand to our U.S. headquarters in Miami, Polyflake® has led corrosion protection with field‑proven technology and a global presence. The results below summarize typical performance for our glass‑flake reinforced systems.

* Performance varies by system, film build, substrate, and service conditions. Always consult the latest technical datasheet and project specification.

“Trusted worldwide, Polyflake Products deliver unmatched anti-corrosion protection.”

POLYFLAKE® delivers superior protection in the toughest environments—marine, industrial, and public infrastructure. Its advanced coating resists heat, chemicals, and abrasion, ensuring long-lasting performance where others fail.